-

send us mail

wiredrawing@wiredrawingmachine.net

We supply wire galvanizing machines in two types: electro galvanizing line and hot dipped zinc coating production line. They work with wire drawing machine, annealing furnace and other facilities, served as auxiliary devices for galvanized wire manufacture.

Electro Galvanizing Machine

Electro galvanizing line is used for zinc plating on black iron wire. The machine is designed with most advanced technology, with sealed acid pickling, no acid smell during processing. The finished electro galvanized wire surface is shinning and uniformly smooth. The wire is widely used in construction, handicraft, wire mesh, wire fence, binding and other fields.

| Galvanizing Machine for Electro Galvanized Wire Production Line | |

| Model No. | CJ-EG30-50 |

| Wire diameter | 0.6mm - 4.5mm |

| Tensile strength | 30-50 kg/mm2 |

| Zinc coating | 10-30 g/m2 |

| Tank material | PP material |

| Number of wires | 4 wires, 8 wires, 10 wires, 20 wires, 28 wires,30 wires, 40 wires or on customer needs |

Hot Dipped Galvanizing Wire Production Line

The hot dip galvanizing device is used for zinc or zn-al ( zinc aluminum alloy) coating of the drawing wire. It is used after the wire rod going through drawing and annealing. Hot dip zinc coating line is usually used as parts of Galvanized Wire Production Plant, work along with Wire Drawing Machinery.

CJ-HG Zinc Coating Line offers the following benefits:

Metal zinc bath; immersed heating nozzle; top heating nozzle; outside heating burner; nitrogen wiping; pad wiping system; a wide zinc coating thickness ranges from 60 to 300g/square meter; efficient water cool and air cooling system; continuous hot dip galvanizing of wire.

Process Flow of Hot Dipped Galvanized Wire

Steel wire rod - C Wire Drawing - Pay-off stand ( wire releasing)  gas pipe annealing furnace (heat treatment)

gas pipe annealing furnace (heat treatment)  air cooled

air cooled  water tank (pickling system)

water tank (pickling system)  Primary assisted plating solvent tank (plating assistant ) - Primary drying furnace (drying after plating assistant)

Primary assisted plating solvent tank (plating assistant ) - Primary drying furnace (drying after plating assistant)  Hot dip zinc coating pan (hot dip galvanized of steel wire )

Hot dip zinc coating pan (hot dip galvanized of steel wire )  porcelain mold or asbestos wipe (Coating wiping )

porcelain mold or asbestos wipe (Coating wiping )  water cool after hot dipped galvanizing

water cool after hot dipped galvanizing  air cool after hot dipped galvanizing

air cool after hot dipped galvanizing  wire collection

wire collection

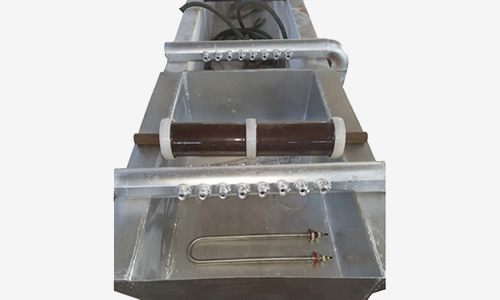

The steel wire should be cleaned quickly to meet the requirement of hot-dip galvanizing speed. The pickling system can ensure the reliable pickling efficiency, so that the steel wire can reach the clean surface before plating under the scouring of hydrochloric acid. Tasteless pickling tank made of PP composite material. Acid concentration can be controlled according to process requirements.

Hot dipped galvanized pot

The zinc pot with heating system is installed on the top end of the zinc pot and opposite sides of the pot. The temperature of zinc liquid in the working area of the zinc pot remains smooth at same level.

Pot size: 3000 * 1600 * 600 (mm)

Temperature range: 440 ~ 460 °C

Zinc pot melting amount: 3 tons

Coating wiping:

Porcelain mold or asbestos wipe;

Galvanized 30 ~ 150g /m2 or 60 to 300g zinc layer

Typical Finished Products: