-

send us mail

wiredrawing@wiredrawingmachine.net

We supply machinery and production line for steel wire (galvanized, mild steel mill finish, annealed and powder coated), ss wire and other metallic wires.

Our machines are well sold for over thirty years in China and in many countries or regions in South-east Asia, Africa and South America. We value our reputation and have wond customers by delivering products and services exceeding customers expectations.

We provide on-site installation, training, or video instruction for our customers, our customers never need worry about after-sales services.

Continuous Pulley Wire Drawing Machine

Continuous Pulley Wire Drawing MachineTo draw the low carbon, medium carbon, high carbon wire, also copper and aluminum wire.

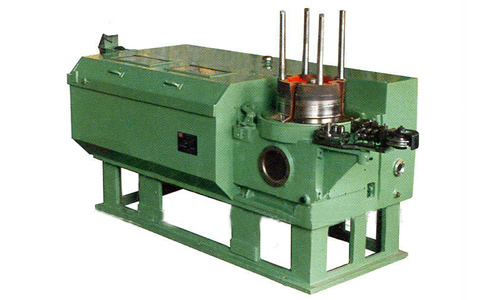

Dry Type Wire Drawing Machines

Dry Type Wire Drawing MachinesBoth Single Block Type and Continuous Multi-block Type, for metallic wire drawing.

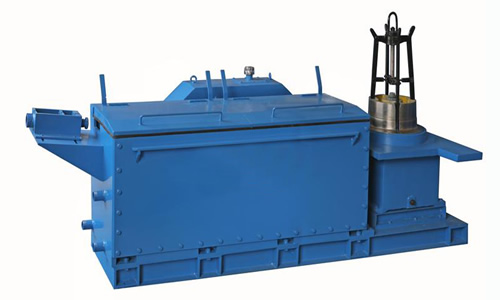

Wet Type Wire Drawing Machines

Wet Type Wire Drawing MachinesThe water-tank series wire-drawing machine is designed with European and American advanced technology.

Straight Line Wire Drawing Machines

Straight Line Wire Drawing MachinesDesigns: Diameter 760 mm block, No. of block: 9, Wire inlet size: 8/7 mm, Material: High carbon wire.

Steel Wire Galvanizing Machine

Steel Wire Galvanizing MachineThe auxiliary equipment for electro galvanizing and zinc bath galvanizing process of the wire after drawing.

Wire Hanger Machine

Wire Hanger MachineAutomatic hanger fabrication with higher capacity, automatic emergency stop, easy operation and simple maintenance.

Trunk Wire Rewinding Machine

Trunk Wire Rewinding MachineAuxiliary devices with wire drawing machine usually, also known as wire coilers.

Uniform Wire Rewinding Machine

Uniform Wire Rewinding MachineThis wire-rewinding machine has an adjustable uniform winding rate, it is a constant tension takingup system.

Wire Discharging Machine

Wire Discharging MachineFor discharging wire in wire drawing or other processings: Diameter of fixed-type block: 550mm, Discharging wire diameter: 1.5-2.5mm

Spring Wire Drawing Machine

Spring Wire Drawing MachineDesigned specially for drawing high carbon steel wires. Diameter of capstan: 600mm. Number of capstan : 8. Inlet diameter : 5.5mm to 8mm

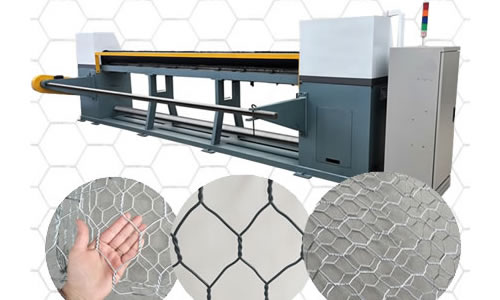

Machine for Wire Drawing and Weaving

Machine for Wire Drawing and WeavingMachine of wire used for hexagonal mesh weaving, supplied with wire coiling machine.

Wire Drawing Machinery Overhead Take-Off Type

Wire Drawing Machinery Overhead Take-Off TypeComplete with blocker, coiler, die, motor, wire pointing machine, micro welding machine

Single Bull Block Wire Drawing Machine

Single Bull Block Wire Drawing MachineThis wire drawing machine is designed for fasteners factories.

LT400.2-15-17-350 Wire Drawing Machine

LT400.2-15-17-350 Wire Drawing MachineMax.diamter of feeding material: 2.6mm. Min.diamter of discharging material: 0.6mm.

LT400.2-13-450 Water Type Wire Ddawing Machine

LT400.2-13-450 Water Type Wire Ddawing MachineDiamer of Roller cylinder: 550mm, Drawing channels: 9time, Maximum feed wire diameter: 5.6mm

LT650.2-9-550 Water Type Wire Drawing Machine

LT650.2-9-550 Water Type Wire Drawing MachineDiamer of Roller cylinder: 450mm, Drawing channels: 13time, Maximum feed wire diameter: 4.2mm

LW630.1-6-350 Wire Drawing Machine

LW630.1-6-350 Wire Drawing MachineAverage compression rate. Approx.25% for low and medium carbon wire material. Approx.20% for high carbon wire material

LD4000.1-1-750 Wire Drawing Machine

LD4000.1-1-750 Wire Drawing MachineMax compresssion rate (approx): 26%. Max drawing force (approx): 2800kgf. Max velocity of block: 82m/min